Australian innovation is at the forefront of sustainable technology as RMIT University, collaborating with partners, continues to develop its PYROCOTM technology. This development focuses on converting treated sewage biosolids into biochar through a high-temperature pyrolysis process in an oxygen-free environment. Recent findings indicate this technology offers a promising alternative to petroleum-based products and presents a sustainable way to reduce carbon dioxide emissions.

Years of collaboration between RMIT University and partners, including South East Water and Intelligent Water Networks, led to PYROCOTM nearing commercial application. The project secured $3 million from the Australian Government to construct a demonstration plant at a South East Water recycling facility next year, underscoring the commitment to integrating advanced technologies into circular economy initiatives.

"PYROCOTM was close to commercial-ready scale," said Professor Kalpit Shah from RMIT University, according to Tech Xplore. The technology was successfully trialed in processing biosolids from five Australian water utilities to create biochar, essential for scaling up to meet industry demands.

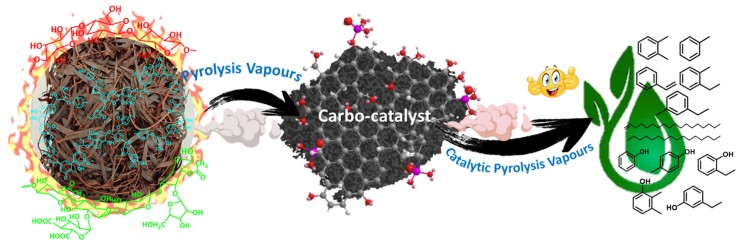

Moreover, biochar derived from biosolids demonstrated potential to replace expensive catalysts traditionally used in extracting oils from biomass. The latest research by the RMIT team, in partnership with the Indian Institute of Petroleum and published in Renewable Energy, showcases its efficacy in producing phenol-rich bio-oil. This bio-oil, containing high levels of phenolics and hydrocarbons, could have transformative uses across industries such as electronics, construction, and automotive, enabling cost-effective alternatives to petroleum-based products.

Lara Olsen, Managing Director of South East Water, acknowledged the significance of the recent PYROCOTM trials. She emphasized the environmental impact, stating, "we're tackling a national challenge by harnessing cutting-edge technology with the potential to destroy 99.99% of PFAS in biosolids," as reported by Australian Manufacturing. This aligns with the stricter PFAS regulations in the PFAS National Environment Management Plan 3.0 and reflects a broader vision of sustainable environmental innovation.

Manish Pancholi, CEO of Aqua Metro, expressed enthusiasm for the project's future, highlighting the opportunity for decarbonization and circular-economy benefits. "Aqua Metro is excited and proud to have been awarded this Cooperative Research Center Project (CRC-P) grant, leading the commercialization of PYROCO technology along with our RMIT, South East Water, Iota, and other partners," Pancholi said, as reported by Man Monthly.

The collaborative effort among RMIT University, Aqua Metro, South East Water, and other stakeholders exemplifies an innovation-driven approach to addressing environmental issues. By converting PFAS-contaminated biosolids into PFAS-free biochar, the PYROCOTM project aims to prevent landfill disposal and contribute to a sustainable supply chain for valuable chemicals. The potential global market impact is considerable, with a projected market value for biochar of $3.3 billion by next year.

© 2025 University Herald, All rights reserved. Do not reproduce without permission.